Compac's refurbished showroom

About this Project

To meet their growing business needs, global technology manufacturer Compac Sorting Equipment needed to expand their prototype capabilities from 250m sqm to approx 1000 sqm. The original floor had surface pitting, oil contamination and uneven surfaces due to a mix of different leveling compounds. The challenge for Topcoat was to transform a pitted and delaminated concrete base into a smooth and stylish new floor of showroom standard.

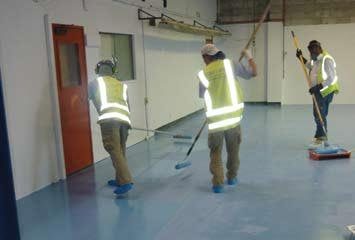

The project involved an initial grind, kango-ing off loose delaminated topping, laying an epoxy pre-fill to level uneven areas and a re-grind. The final step was to apply three coats of PPG Amerlock 400 roll-on epoxy.

When initialling scoping the job, Gavin Reeve says Compac looked at five or six different companies – but Topcoat stood out as they tailored the solution to the problem, rather than providing a one-size-fits-all solution. This carefully-considered approach was appreciated by Compac, particularly as it resulted in cost savings overall.