Beverage Production

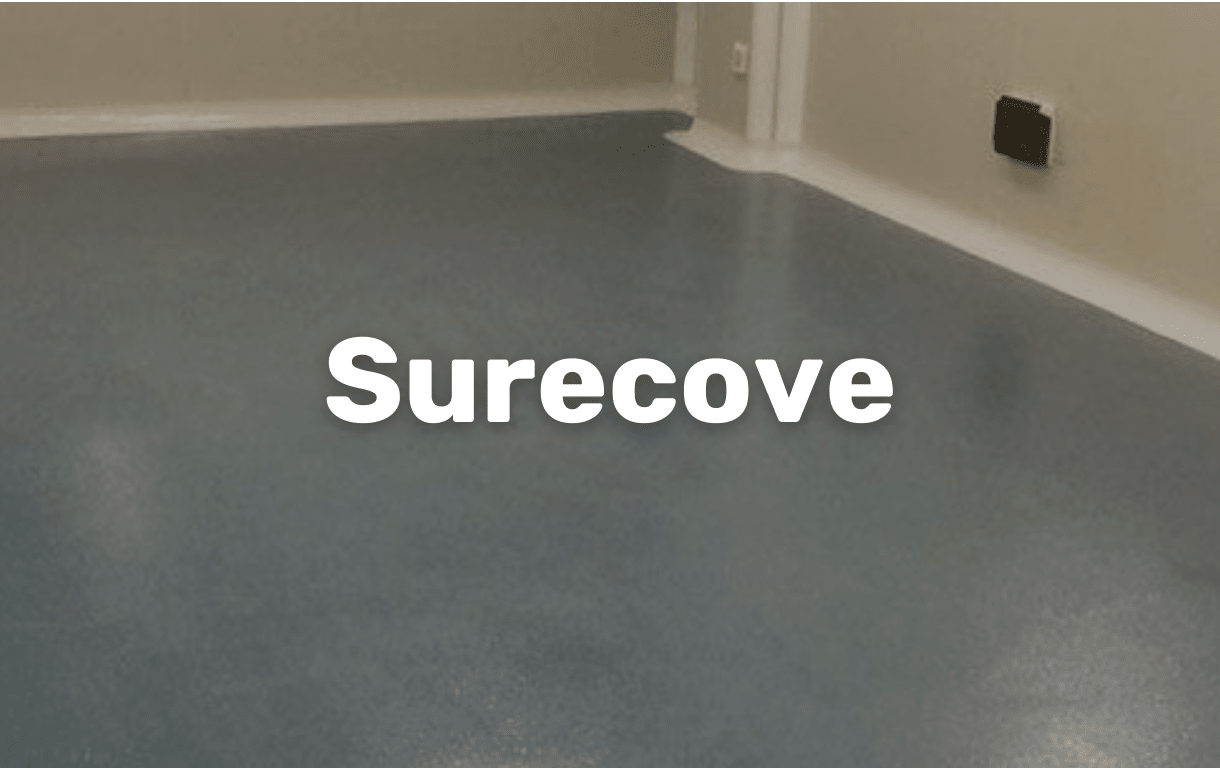

Durable and slip resistant flooring

The flooring in beverage production facilities is a critical aspect of the overall infrastructure. It plays a crucial role in maintaining hygiene, safety and operational efficiency. The choice of flooring should align with those specific needs and processes and meet specific requirements:

Hygiene Standards: Flooring should be easy to clean and sanitize to meet strict hygiene standards, preventing contamination.

Slip Resistance: To enhance safety in areas where liquids may be present, reducing the risk of accidents.

Chemical & Temperature Resistance: Given exposure to various chemicals used in beverage production, where temperature variations may occur, our flooring resist damage to ensure durability.

Durable and Resilient: Our flooring solutions are durable enough to withstand heavy equipment, foot traffic, wear and tear over time and other operational demands.

We work across several beverage industries:

- Wine and beer production.

- Breweries and Microbreweries vineyards

- Craft breweries

Our Trade Certifications set us apart

Our Telarc certification to the AS/NZS ISO 45001:2018 Occupational Health and Safety Standard, coupled with our team of BCITO trade-certified professionals, ensures the utmost quality assurance and expertise for our customers.

Request a Quote For Your Project

Request a Quote For Your Project

Related Projects

Some of Our Happy Clients

“From the moment we met the Topcoat Sales representative and through to the completion of the project, the team listened to our requests and were meticulous in their workmanship. We are thrilled with the outcome!”

“TopCoat were very well organised, with no disruption to our business at all, we’re very happy with the results.”

“The Waterview Connection represents another successful project and the technical skills demonstrated by Topcoat was particularly impressive.”